Jl. Haji Ten Raya No 4 Jakarta

Pasang Aluminium Kaca

Kontraktor Spesialis Produk Aluminium, Kaca & ACP untuk Interior & Exterior Bangunan

Bidang Usaha :

- Produk Aluminium Kaca & ACP Terpasang Rapi & Bergaransi Pada Bangunan Anda.

- Perawatan / Perbaikannya Produk

- Penjualan Bahan Aluminium Composite Panel Tanpa Pemasangan

- Jasa Kontraktor Pemasangan ACP untuk luasan tertentu

About Us

CV Berkah Lestari Jaya adalah Perusahaan specialis Aluminium, Kaca, ACP.

Berdiri semenjak 2010, Beralamatkan Jl. Haji Ten Raya no 4. Rawamangun Jakarta Timur

Produk Unggulan

Aluminium Composite Panel yang akan menggantikan kayu dimasa depan dengan warna menarik, awet berkualitas

Jual Partisi kaca untuk sekat ruangan kantor dan depan toko agar View lebih lega seperti etalase raksasa

Fasade exterior full kaca yang selalu ada pada bandara, kantor terutama Bank dan ruko.

Kaca dengan view luas dari dalam yang membuat tetap irit listrik karena menggunakan kaca oneway reflektif yang membuang panas matahari.

Dengan Curtain Wall bangunan terlihat lebih berestetika dengan biaya murah, proses cepat, low biaya maintenance.

Layanan

Kami melayani penjualan produk Aluminium Kaca & ACP termasuk pemasangan dengan rapi dilokasi sesuai ukuran yang ada.

Layanan ini kami melakukan penjualan sekaligus pemasangan dilokasi dengan rapi, tuntas serta bergaransi.

Costumer Cukup membayar dengan 1 nominal harga dan produk yang dibeli sudah tuntas terpasang.

Layanan ini untuk costumer yang membutuhkan jasa tukang Aluminium atau tukang Kaca yang terbiasa dengan produk aluminium & Kaca.

Biasanya costumer kami sudah mempunyai unit barang namun tidak tahu cara pemasangan, bisa juga takut resiko kaca pecah sehingga memerlukan jasa spesialis.

Seperti membeli produk dari market place online dengan harga lebih murah, atau memindahkan lokasi yang baru atau relayout

Kategori Produk

Produk untuk exterior dan interior banguna dari bahan bijih aluminium yang cetak menggunakan moulding dan diberikan nama / kode profile.

Item Produk Aluminium :

- Aluminium Composite Panel

- Kusen Aluminium

- Pintu Aluminium

- Jalusi Aluminium

- Neon Box Aluminium

- Plafon Spandril

Perbaikan produk aluminium kaca pada bangunan. Produk yang sudah terpasang terkadang perlu untuk di pindahkan, re-layout, penggantian sparepart dan komponen yang aus, bocor dan pembaharuan sealent yang sudah expire

Item Jasa :

- Resealent ulang nat agar tidak bocor pada acp, curtain wall, partisi kaca

- Penggantian sparepart pintu kaca seperti floorhinge, patch fitting, handle yang patah

- Memindahkan unit produk kelokasi baru atau re-layout

- Penggantian kaca yang pecah

Produk kaca pada bangunan

Produk Kaca & Jasa kaca pada bangunan

Item Produk Kaca :

- Pintu Kaca

- Partisi Kaca

- Kaca Tempered

- Kaca Laminate

- Railing Tangga

- Kanopi Kaca

- Curtain Wall Kaca untuk Fasade Bangunan

Feature

Tukang Ahli Specialis

Tukang Spesialis Aluminium & Ahli Pasang Kaca

Professional

Tim kerja yang bisa diandalkan, Ramah, Komunikatif, Gesit.

Pengalaman

Semenjak 2008 memulai usaha dibidang tukang kaca

Cepat, Rapi, Bagus, Bersih

Pengerjaan Rapi , Cepat, Rapi, Bersiih

Layanan 24 Jam

Jadual pengerjaan yang flexible Bisa dimalam hari seperti Mall, Apartemen, Hotel, Restoran

Harga Murah & Original

Harga murah dengan produk yang selalu original serta bergaransi

Review Bagus

Memiliki Track Record dan Portofolio hasil pekerjaan

Legal & Resmi

CV Berkah Lestari Jaya perusahaan legal dan resmi yang bisa bertanggung jawab memberikan garansi

Portofolio Project

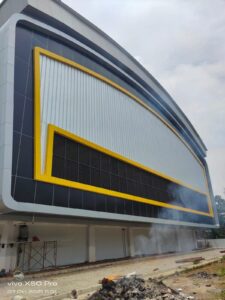

Pemasangan ACP Seven Untuk Fasade Dinding Exterior Bangunan di PGTI Kamayoran Jakarta Utara. PIC : Bp Komarudin

Pemasangan Curtain Wall Kaca Di Kantor Pribadi H. Anda Suhanda Serang Banten

Partisi Kaca Frameless. Menggunakan Kaca Tempered 12 mm di PT Unggul Semesta Cikarang

Pemasangan Pintu Kaca Frameless Model Sliding. Full Tempered 12 mm di Rumah Bp Bilal. Bandung

Welcome Costumers

Support By

Brand Aksesories Aluminium & Kaca

Content

Informasi ACP Seven

Aluminium COmposite Panel Info ACP Seven Informasi Mengenai ACP Seven, katalog Warna, warna motif urat kayu, distributor, spesifikasi, manfaat, kekurangan

Perbandingan Harga Bahan ACP

Info Aluminium COmposite Panel Perbandingan Harga ACP Komparasi harga material bahan acp dari 6 Merk Butuh Informasi & Konsultasi ?

Tukang Aluminium

Anda butuh tukang aluminium ? atau mencari upah jasa borongan tukang specialis aluminium dengan perlatan lengkap ? Kami menerima upah

Tukang Kaca

Apakah Anda Mencari Tukang Kaca? Apakah anda perlu merelayout, pindahan, bongkar pasang, menggunakan kaca bekas yang sudah ada di tempat

Pintu Kaca Lipat

Pintu Kaca Lipat atau Folding Glass Door adalah Pintu Kaca yang cara membukannya dengan cara melipat daun pintunya. Model lipat

By Phone

Jl. Haji Ten Raya no 4 RT 006 RW 003 Kelurahan Rawamangun Kecamatan Pulogadung Jakarta Timur

Senin - Sabtu 09:00 - 22:00, Minggu : Janjian

By email & Newsletter

Thanks & Cheers

Terima Kasih atas kepercayaan Costumer kepada kami dan menjadikan CV Berkah Lestari Jaya menjadi rekan abadi dalam setiap pengerjaan produk kaca dan aluminium untuk interior dan exterior

Salam Hormat,

Nado Velka

Direksi